Colleges and universities are moving past the restrictions imposed by the pandemic into a world that offers more freedom to shape to our desires and expectations. In the education sector, schools no longer have to stay remote, but continue to seek options for offering remote and hybrid options to their student populations. There are external factors that are pushing how education technology will change in 2023, along with internal shifts in culture that continue to shape higher ed technology.

Read on for some insights from our team about big tech trends in the higher education space for the coming year.

Keep Investing in Cybersecurity for Higher Ed

Higher ed institutions are at the top of the target list for cybercriminals. They tend to be less prepared than organizations across other sectors to handle cybersecurity incidents, with outdated infrastructure and slow investments into new technology.

Universities manage large volumes of valuable data on students and research, and that data is an easy and profitable target. Education and research institutions were targeted by cyberattacks an average of 1,065 times per week in 2021—and that number continues to. In response to these risks, we’re seeing a shift in culture and technology to be better aware of and prepared for security breaches.

Technologically, most institutions are investing more heavily in software upgrades, security monitoring support, and newer devices. Some newer models of laptops and desktops have security measures built into their hardware. HP, for example, continues to offer new developments in HP Wolf Pro Security, mainly using hardware-enforced threat containment that’s built into the motherboard with micro-virtual machines. With these micro-VMs, applications and webpages are kept isolated from each other; meaning that if a file contains malware, it’s trapped and destroyed before it can infect the rest of the computer or other endpoint.

But a large portion of cyberattacks occur because of user error. A student or faculty member may open a bad email link, or an administrative employee might use the same password for all of their important accounts. This is why education in cybersecurity is an essential part of the equation: all users on a university’s network need to be comfortable using multi-factor authentication (MFA), and competent in managing their passwords and documents.

Many Students, Faculty, and Office Workers are Staying Remote

While many institutions have gone back to in-person instruction, hybrid and remote options for work and study are here to stay. It’s a smart move for universities to continue investing in these options, particularly for attracting top-notch faculty and admin, since offering flexible work options can attract a wider pool of talent.

While classroom instruction, research, and back-office operations have different needs and systems, there are a few elements that they have in common when it comes to hybrid work.

- Investing in more cloud-based services. Cloud services are essential for collaborating on, sharing, and securely storing documents when users aren’t all working from the same location or server.

- Expand the fleet of collaborative software. It’s becoming easier to customize Zoom, Microsoft Teams, and other conferencing platforms to suit an institution’s unique needs. Various tools can also be integrated with productivity tools like Slack, Asana, and Notion. In many ways, hybrid tools are making communication more thorough, efficient, and equitable in-person interactions.

- VPN and MFA support. For any collaboration, it’s important that organizations offer secure ways to access and share work. Virtual Private Networks (VPNs) offer an added layer of security for endpoints outside of a centralized office, so many companies are making VPNs a requirement. Multi-factor authentication (MFA) is another layer of security that ensures shared drives are securely locked down.

Save Money in the Long Run

Upgrades to security and hybrid work systems require investment up-front in both time and money. But investing in modern, reliable, and secure systems that support faculty, staff, and students help create a healthy work environment that retains top talent. Further, because cyberattacks can be astronomically expensive to recover from, these investments are strategic and wise for the money that they’ll save..

We recommend that universities partner with endpoint device specialists to support their existing IT teams, rather than burdening the IT department with work that’s outside of their daily scope. Specialists will help higher ed institutions make strategic upgrades within their budget, guiding them to the right combination of devices, software, infrastructure, and services to maximize productivity and communication, and minimize the risk of losing data or succumbing to cyberattacks.

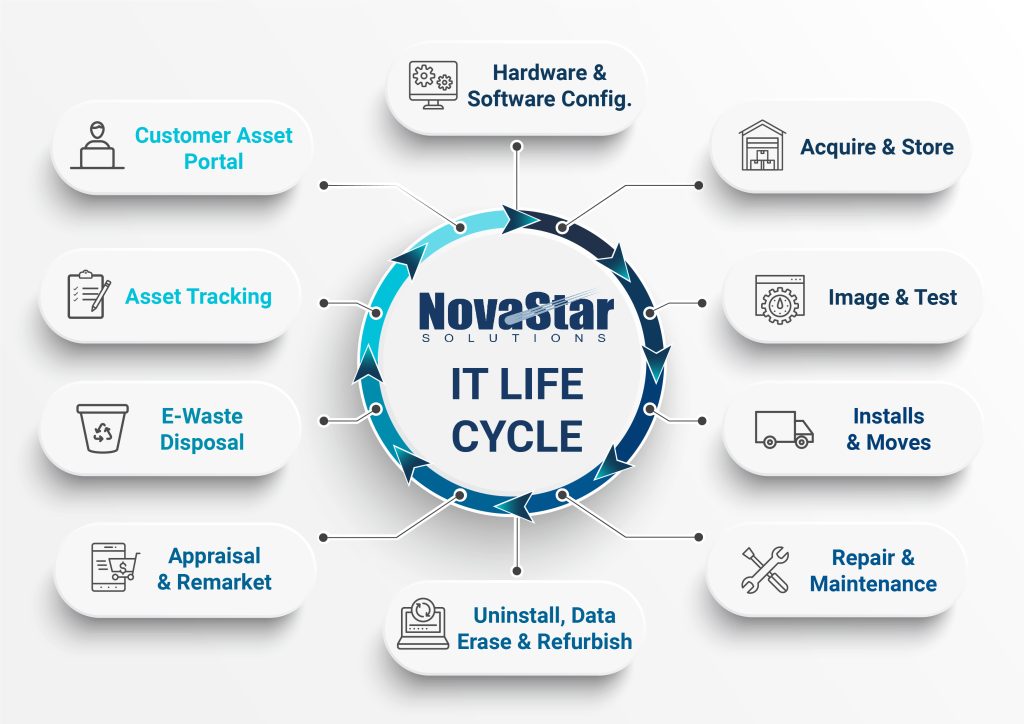

At Novastar, we’re experts in creating singular, centralized ways to manage each and every device in your ecosystem. Higher education institutions need support in reducing complexity and establishing ongoing maintenance routines. Doing so ensures that you stay on top of emerging issues rather than putting out fires or missing out on opportunities that arise.

Get proactive about device lifecycle management in the new year by contacting Novastar. We’ll help you assess your educational ecosystem and determine what type of lifecycle management strategy will work best for you.