Wednesday, June 15, 2022 from 10:00 AM to 2:00 PM EDT

Novastar HP 3D Demo Center | 12901 Newburgh Rd.| Livonia, MI 48150

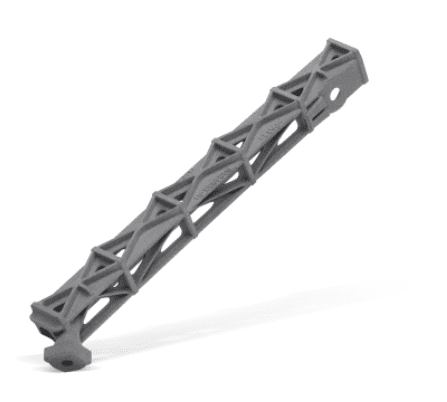

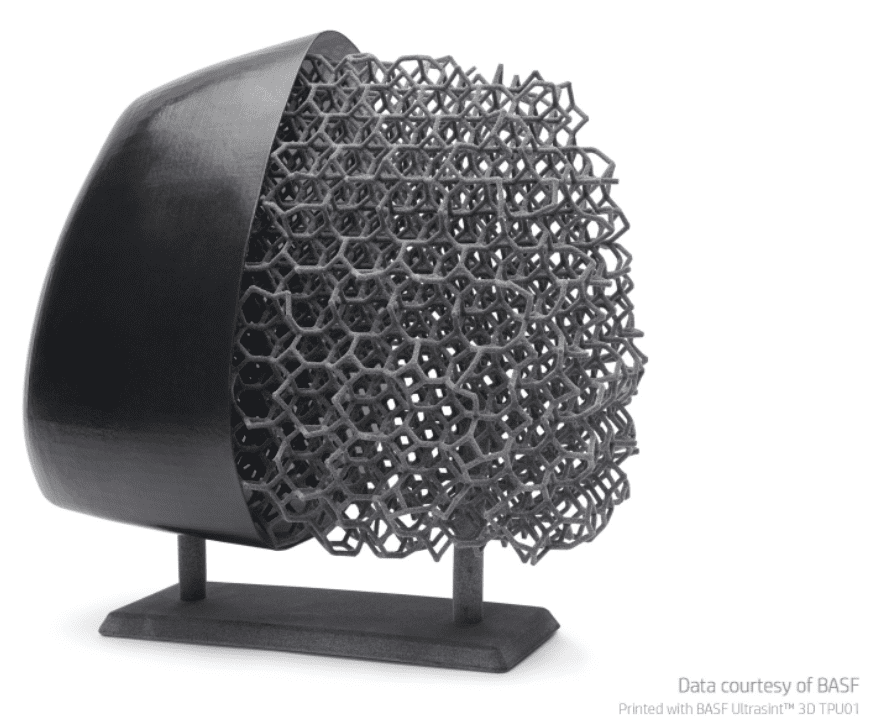

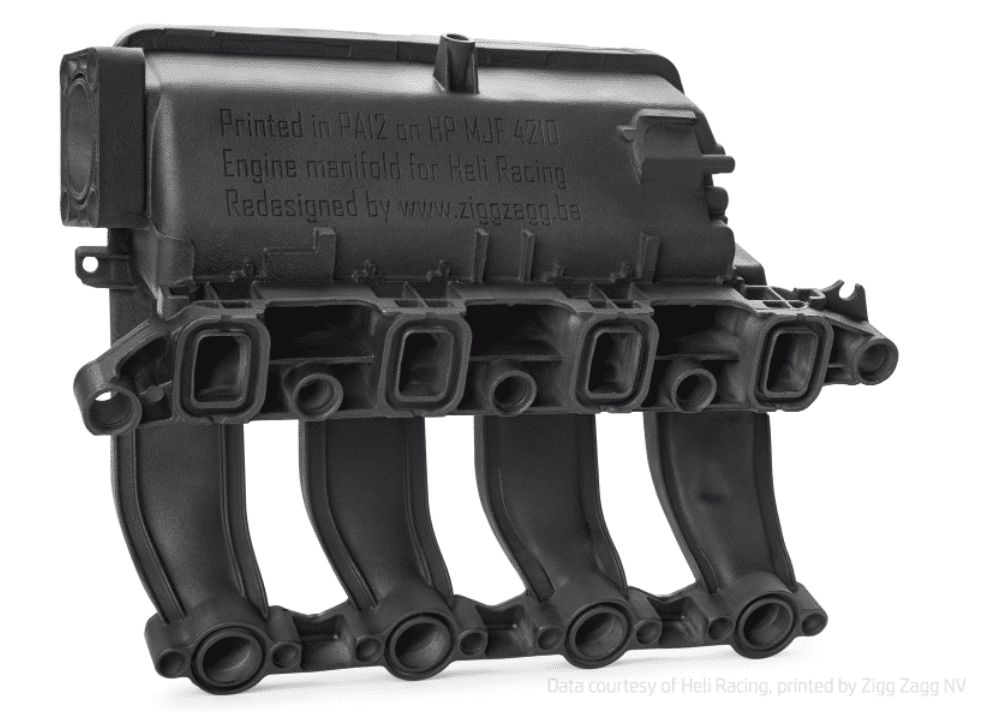

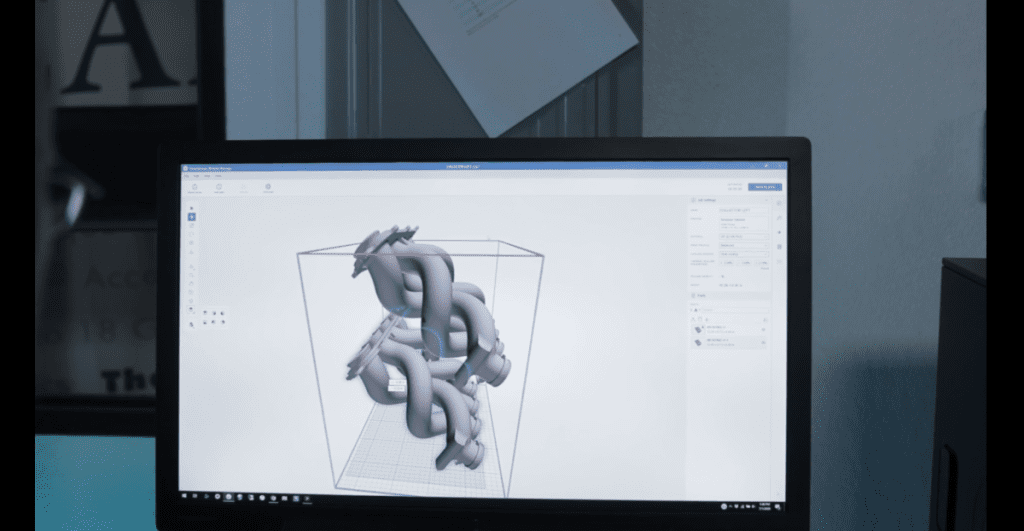

Join Novastar for lunch and a technical presentation on Enhancing Automation with 3D Print. We’ll discuss materials available for industrial MJF, showcase design optimizations, provide information on cost benefits, and much more.