3D Print for Automotive Prototyping, Tooling, and Production

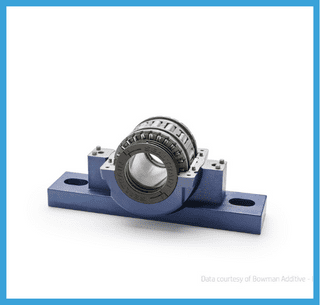

Automotive manufacturers have led the way in using novel materials and technologies for decades. In 2023, as the demand for sustainability, electric vehicles, and self-driving cars soars, 60 major car brands are embracing 3D printing technology for both prototyping and high-performing functional parts. Specifically, HP Multi Jet Fusion (MJF) 3D printing is helping car and vehicle manufacturers reduce costs in parts production while boosting operational efficiency.

HP 3D Print Advantages for Automotive

-

Applications for Prototyping and End-Use Parts

-

Better Build Quality

-

Accurate Fine Details

-

Design Freedom (no supports needed)

-

Sustainability (powder is recycled)

-

Faster Build Speeds

-

Best Cost Position (tooling costs are eliminated)

Additive Manufacturing Applications in the Automotive Sector

- A Spanish automotive parts supplier (Continental Automotive Spain S.A.) used MJF printing to develop a pneumatic gripper that helped them cut down on time when tooling new parts.

- At Jaguar Land Rover, car engineers are using HP Multi Jet Fusion to make brackets and interior trim for production vehicles.

- General Motors’ new 15,000 square foot Additive Industrialization Center counts HP MJF machines among its 3D printing fleet for prototyping, tools, fixtures, and end-use parts.

Case Studies: HP Jet Fusion 3D Printing Automotive Applications

Eagle cut overheads on low-volume parts while maintaining classic Jaguar part quality for collectors.

In the fast-paced world of auto racing, Dundon Motorsports stays ahead by 3D printing parts for Porsche GT racecars with HP Multi Jet Fusion Technology.

Porsche is revolutionizing sporty seating with the concept study “3D-printed bodyform full-bucket seat.”

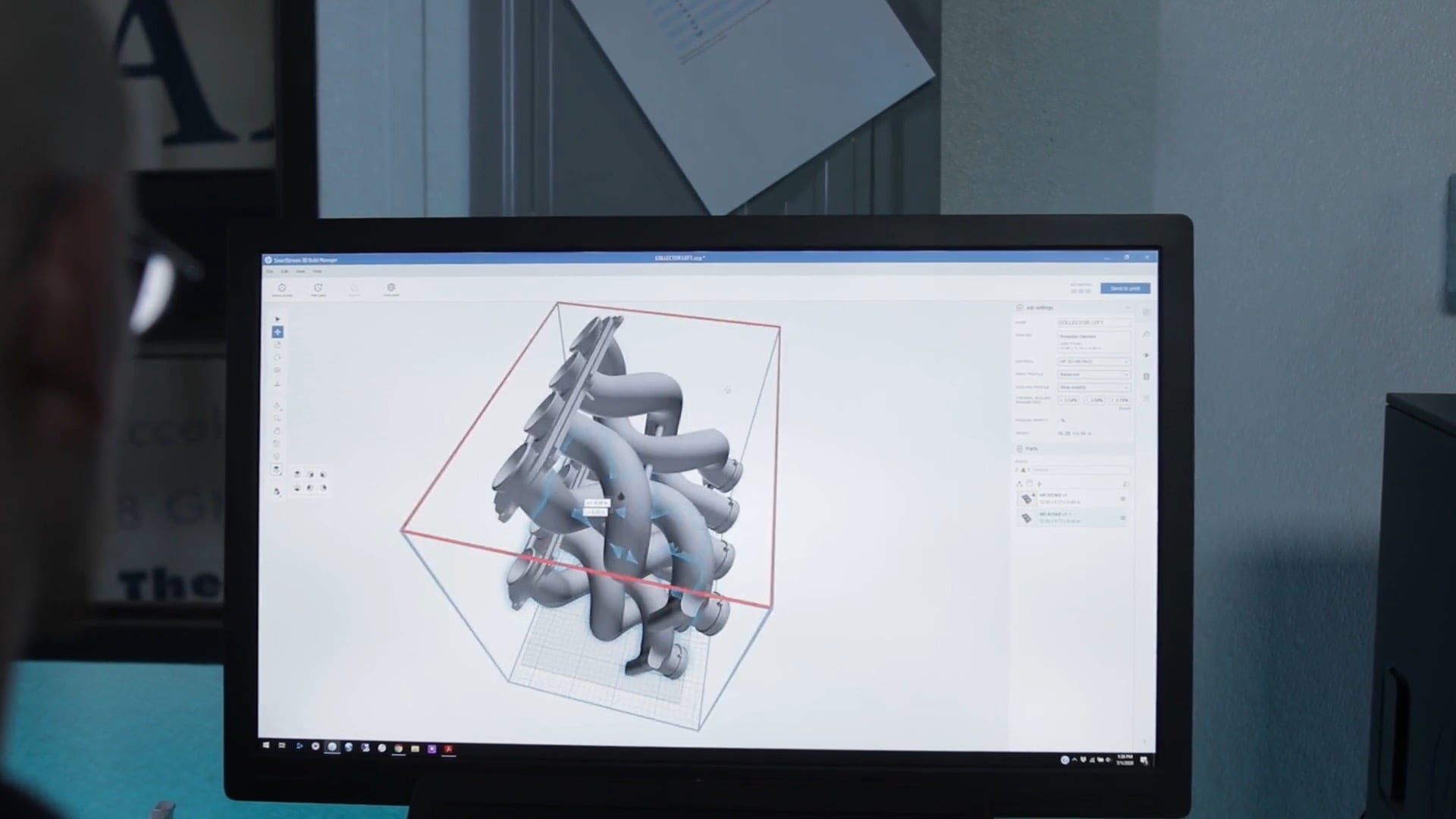

Using 3D scanning methods and reverse engineering, Heli Racing simplified the production of their race car manifold.

The need to produce over 1000 wire harnesses on a fast timeline was met by HP 3D Multi Jet Fusion Printing.

Peugeot is reinventing car accessories thanks to innovative 3D printing technology and a new, flexible polymer.

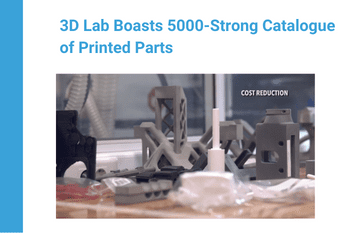

A pioneering 3D printing laboratory of printable parts numbers over 5000, offering solutions for every phase of the manufacturing process at Ford Almussafes.

MotoSpirit introduced technical improvements to their motorbikes by designing and 3D printing battery stacks for their battery packages.

CAF replaced metallic parts in their train systems with Jet Fusion printed parts, enhancing strength and performance.

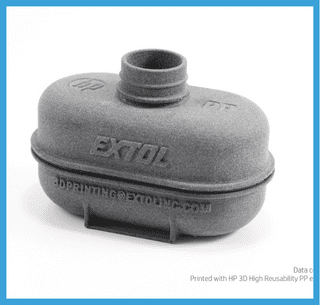

Extol leverages the manufacturing industry’s familiarity with polypropylene combined with HP MJF technology to decrease time to market through design validation efficiency.

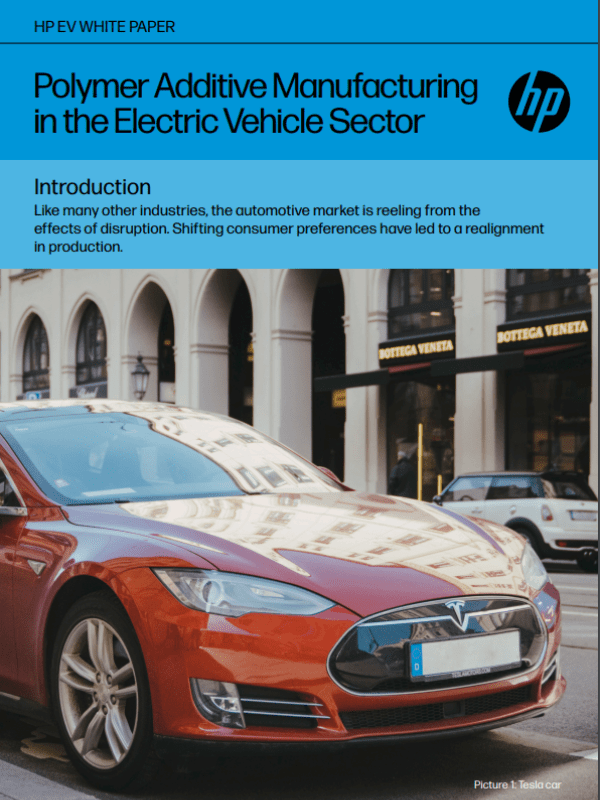

White Paper: Polymer Additive Manufacturing in the Electric Vehicle Sector

The digital technology inherent in 3D printing, combined with generative design and other software tools, can help engineers reduce the weight of individual parts while also reducing the overall number of parts, and simplifying assembly of larger components.

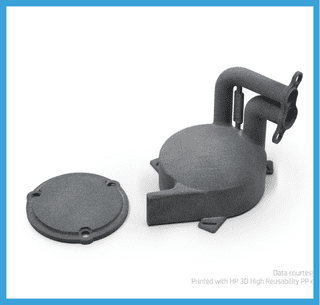

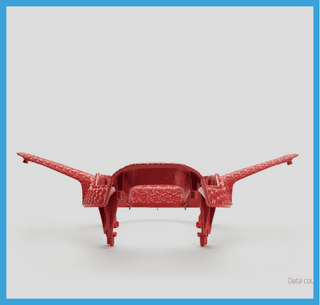

HP Multi Jet Fusion 3D Printed Automotive Parts

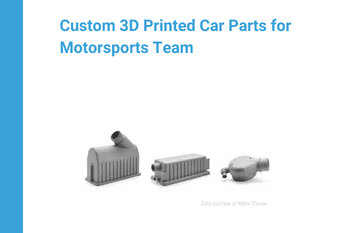

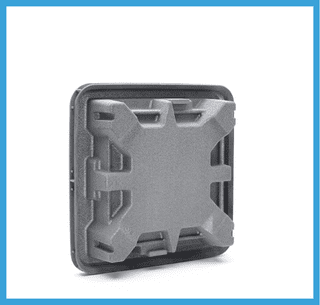

Air duct printed with HP JF 5200 3D and HP 3D High Resolution PA12. Advantage: no molds, optimized air flow.

Automotive AM eBook 2022

Paving the road for more efficient production and vehicles with Additive Manufacturing

3dpbm’s downloadable e-Book on Automotive AM includes the following articles:

- How much will the EV revolution drive AM adoption in automotive?

- AM adoption accelerates at Daimler Trucks & Buses

- A conversations with ŠKODA AUTO

- Automotive seating gets an AM revamp

- AM and Automotive: the benefits and opportunities are clear

Video Resources for Discovering HP Jet Fusion 3D Printing Automotive Applications

Tooling Jigs and Fixtures for Automotive Product Development

HP3D Print Applications for the Transportation Industry

Automotive Product Development with HP MJF

Bringing the Best Car to the Track--Faster

Demonstrating the Strength of MJF Printed Parts

Producing Automotive Parts for a Very Tight Deadline

How Additive Manufacturing Accelerates Product Development Cycles for EV

Designing for HP Multi Jet Fusion

3D Printed Parts Add Value in the Automotive Industry

Deloitte University Press Report: 3D Opportunity in the Automotive Industry

This report looks at how Additive Manufacturing (AM) can improve the competitive position of automates and explores the four paths OEMs and suppliers can take to more broadly apply AM. It also explores the drivers supporting the use of AM and associated challenges for large-scale adoption.

HP MJF 3D Print Optimization Opportunities – BMW Rear Motor

- Fluid manifold with integrated hybrid pass-through

- Fluid blade optimization enabled by lower EV temperatures

- Air fan turbine

- Power Management

- Charging – grommets

- Colored Connectors (safety orange)

- Coolant Bottles EV Temp Lower

- Distribution

- Wire Looms / Housing Boxes / Wire Guides

- Hybrid pass-through cable routing

Questions?

With so many options available, the world of Additive Manufacturing for automotive applications can be difficult to navigate. Contact Novastar’s 3D printing experts today for a free consultation. One of our Additive Manufacturing Specialists will be happy to discuss the unique benefits of HP 3D Printers.

"*" indicates required fields